應(yīng)用范圍 | Application Scenarios

硬鉻電鍍:液壓桿、模具、輥軸表面耐磨涂層

Hard chrome plating for hydraulic shafts, molds, and rolls

鍍鎳/鍍金:連接器、電子零件防腐涂層

Nickel/gold plating for connectors and electronics

功能性電鍍:裝飾鍍層、電觸點(diǎn)、電磁屏蔽層

Functional coatings for aesthetics, conductivity, and shielding

環(huán)保鍍鉻替代工藝:三價(jià)鉻、硫酸鍍鉻系統(tǒng)配套陽(yáng)極

Anodes for trivalent and sulfate chromium plating systems

? 核心優(yōu)勢(shì) | Key Advantages

1. 鍍層均勻,結(jié)合力強(qiáng)

? 電流分布穩(wěn)定,解決局部過(guò)鍍或燒焦問(wèn)題

? 提升鍍層致密性,附著力顯著增強(qiáng)

Uniform and durable coating

? Prevents hotspots and ensures even thickness

? High-density, well-adhered deposits

2. 耐腐蝕性強(qiáng),適用于酸性鍍液

? MMO 涂層穩(wěn)定于鉻酸、硫酸鍍液中

? 可連續(xù)運(yùn)行2000小時(shí)以上

High chemical stability

? Resists aggressive bath chemistries (e.g., chromic/sulfuric acid)

? Long-term continuous operation

3. 環(huán)保無(wú)毒,替代傳統(tǒng)鉛陽(yáng)極

? 不釋放鉛污染,滿足RoHS、REACH環(huán)保標(biāo)準(zhǔn)

? 降低廢液處理成本

Lead-free and eco-friendly

? Compliant with global environmental regulations

? Reduces hazardous waste

4. 維護(hù)簡(jiǎn)便,運(yùn)行穩(wěn)定

? 涂層不易剝落,減少停機(jī)更換頻率

? 可清洗再生,延長(zhǎng)陽(yáng)極整體壽命

Low maintenance and long service life

? Strong coating adhesion

? Easy cleaning and reuse

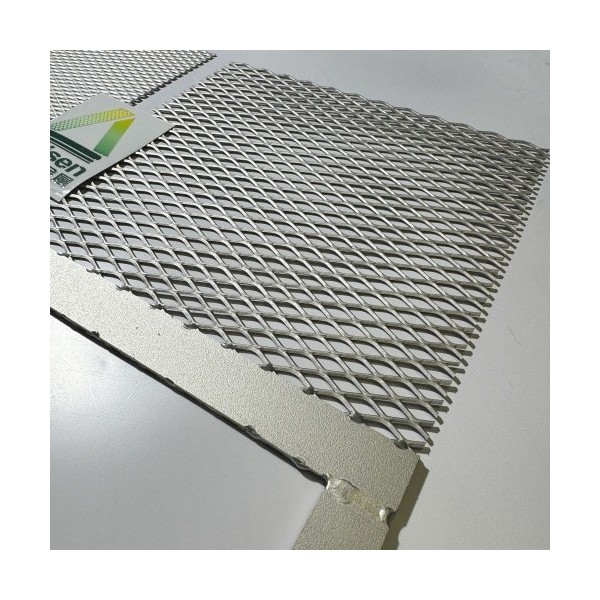

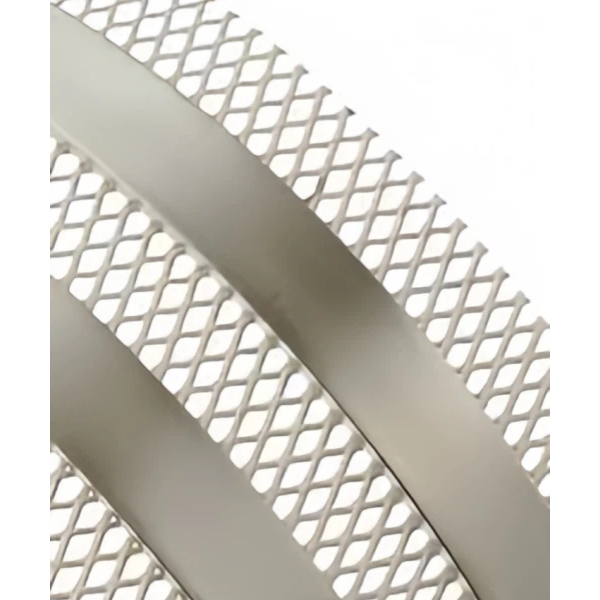

5. 支持多種結(jié)構(gòu)定制

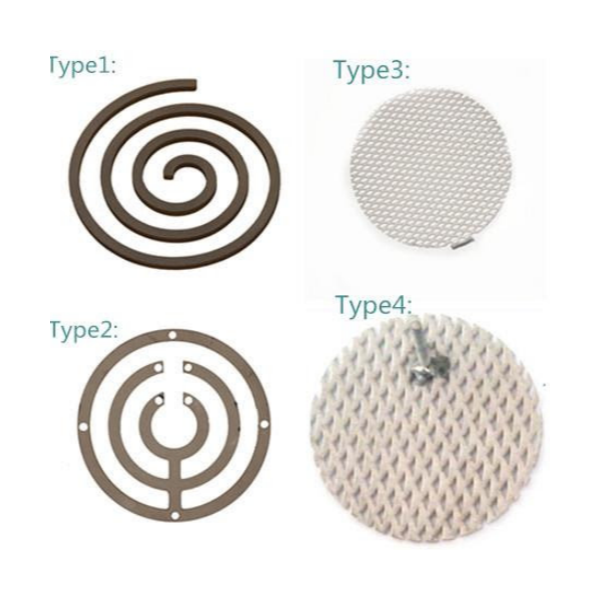

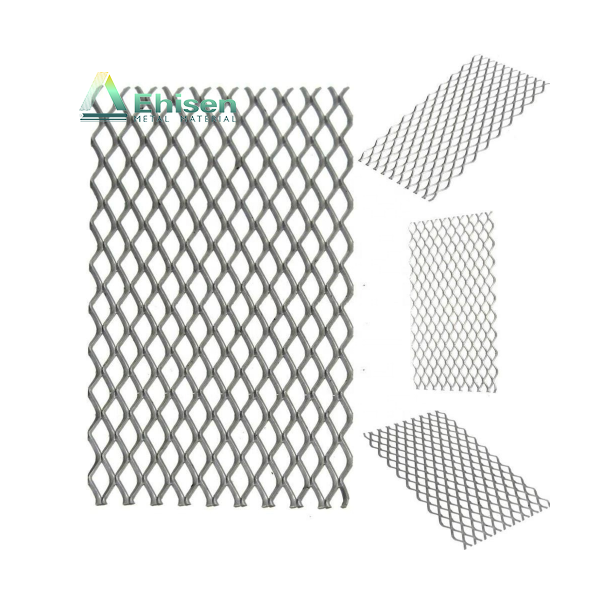

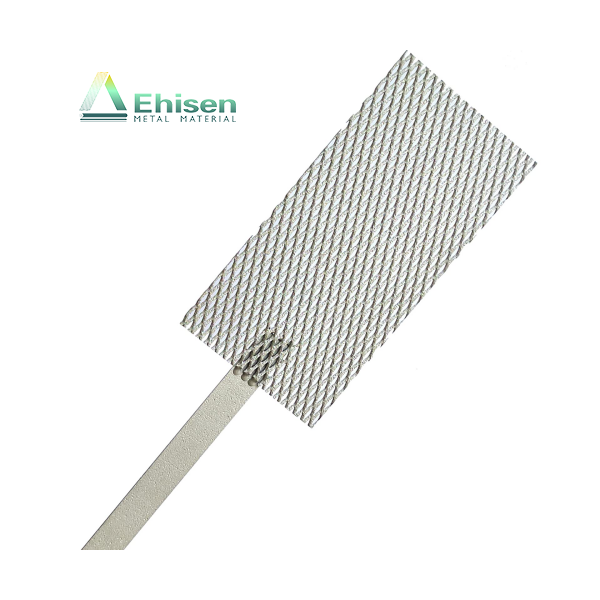

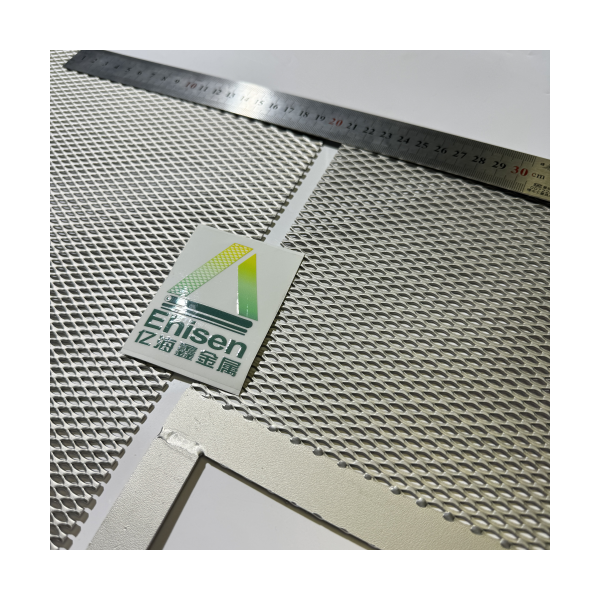

? 網(wǎng)式、板式、棒式、異形陽(yáng)極均可設(shè)計(jì)

? 可配合鈦掛具、導(dǎo)電桿系統(tǒng)一體使用

Customizable to fit all tank types

? Available in mesh, flat, rod, and shaped formats

? Integrates easily with plating fixtures